Replacing painted fire sprinklers is the safe — and often required — option

It’s bad news when fresh paint meets a fire sprinkler. Whether it happens during a remodel, renovation, or home or office improvement, paint can delay or prevent sprinklers from deploying properly and containing fires. And any DIY fix of a painted sprinkler is a warranty-voiding move that could put lives or property at risk while giving inspectors cause to take a sprinkler out of service. That’s why the latest rules in NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems mandate replacing painted fire sprinklers when the paint is “detrimental to sprinkler performance.”

If you’re looking for a replacement sprinkler head, check out our selection of fire sprinklers, including residential and commercial models from Tyco, Viking, Victaulic, and Senju. To understand why, when, and how to replace fire sprinklers that have been painted, read on.

Bad things can happen to those who paint (fire sprinklers)

In 2018, Woodbury, Minnesota-based Dyne Fire Protection Labs tested the response time of three fire sprinklers to see how quickly painted fire sprinklers activate in the presence of heat. These tests, known as plunge tests or “oven heat tests,” measure the time (in seconds) required for a room-temperature fire sprinkler to activate when exposed to a stream of hot air.

Dyne tested each sprinkler model eight times: four times with paint — specifically, a coat of Rust-Oleum Painter’s Touch 2X spray paint — and four times without.

As expected, each of the unpainted sprinklers responded at the appropriate time. But more than half of the painted sprinklers had problems. They activated late, lost water pressure, or never released water at all. Here’s a video of Dyne’s test:

“There is significant variability in the performance of aftermarket painted sprinklers,” says Grant Lobdell, Dyne’s lab manager, in his summary of these tests, “and there is potential for even a drop of paint in the right spot to impact thermal performance.”

While there are instances where paint may be harmless — a document explaining Dyne’s testing methodology adds that paint on the arms of a sprinkler head shouldn’t have any impact on performance — fire authorities and codes have historically taken a very stringent view on painted sprinklers.

The National Fire Protection Association (NFPA), which authors the fire protection model codes and standards widely used in the United States and abroad, has issued past guidelines that require facility owners or managers to remove from service any fire sprinkler with any amount of aftermarket paint found during the annual visual inspection of sprinklers. Only the 2023 edition of NFPA 25 has relaxed the paint-related replacement rules compared to previous editions. Here’s the latest reference (with some emphasis added):

From the 2023 Edition of NFPA 25

5.2.1.1.1* Any sprinkler that shows signs of any of the following shall be replaced:

(1) Leakage

(2) Corrosion detrimental to sprinkler performance

(3) Physical damage

(4) Loss of fluid in the glass bulb heat-responsive element

(5) Loading detrimental to sprinkler performance

(6) Paint, other than that applied by the sprinkler manufacturer, detrimental to sprinkler performance

The words “detrimental to sprinkler performance” were added in 2023 to the rule against paint, granting some leeway about replacement. Previously, any amount of paint would technically qualify as a violation.

Why was NFPA 25 so strict about this situation, and what’s now considered “detrimental to sprinkler performance?”

The Dyne USA test shown above illustrates one major issue: insulating the thermal element and thus delaying activation. But there are other potential problems (some emphasis added):

From the 2023 Edition of NFPA 25

A.5.2.1.1.1 Corrosion, loading, or paint found on the seat of the sprinkler could impact the release of the plug and discharge stream. Corrosion, loading, or paint built up on the deflector could affect the spray pattern.

Two features of fire sprinklers explain why paint can cause a malfunction:

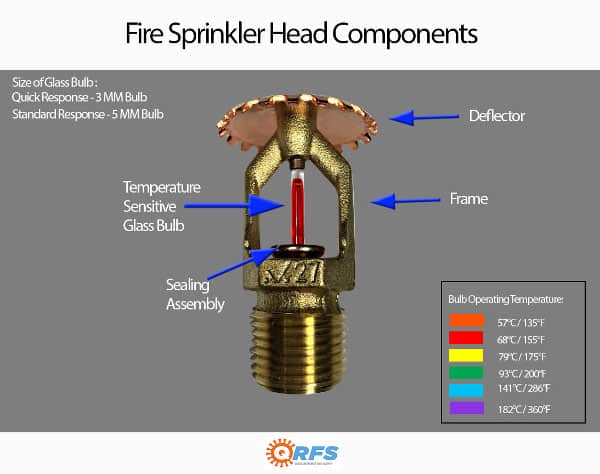

One: sprinkler heads are triggered by heat-sensitive components, usually a glass bulb filled with a liquid that expands as it warms or sometimes a metal link that melts as it heats up. As these elements reach specific temperatures, they detach from the sprinkler head, allowing water to flow into a room. Paint insulates these heat-sensitive elements; as a result, that glass tube or metal link may stay in place far too long, allowing a fire to spread.

Two: pressurized water pours from a sprinkler head after discharging a plug. It’s then distributed throughout a room by a small grooved plate called a deflector. Deflectors ensure that the water discharges in a pattern of a particular shape and size. Paint on a plug may delay it from unseating or impact the water stream. And paint on a deflector may distort the water’s pattern, rendering the sprinkler ineffective.

Click here for an in-depth explanation of the types and functions of fire sprinklers.

In short, water might not go to the right places or at the right time when there’s paint on certain parts of a sprinkler head. Determining what paint, where, and how much could impact performance can be determined by a qualified inspector or authority having jurisdiction (AHJ). But a general rule of thumb is that paint on or very near any of the key parts will be an issue, including the heat-sensitive element, sealing assembly, or deflector. In contrast, a drop of paint on the frame arm might not be a problem.

To learn more about what may or may not qualify, read this blog: “Fire Sprinkler Head Replacement: Changes to NFPA 25 Rules.”

Also, note that many jurisdictions still officially reference previous editions of NFPA 25, so local inspectors may apply a stricter standard than the latest rules. If this is the case, you can make a case for using the 2023 edition references if a tiny amount of paint is on a non-essential part of the sprinkler, as these prescriptions represent NFPA’s latest fire protection research.

Using solvents and scrubbing painted fire sprinklers will do more harm than good

In only one scenario does NFPA 25 explicitly permit cleaning a fire sprinkler head — and it’s not when it’s painted:

From the 2023 edition of NFPA 25

A.5.2.1.1.1 In lieu of replacing sprinklers that are loaded with a coating of dust, cleaning sprinklers with compressed air or a vacuum is permitted, provided that the equipment does not touch the sprinkler.

Touching the sprinkler head isn’t permitted even for a task as simple as dust removal, and with good reason: doing anything to a fire sprinkler head can be a risky business. The heat-sensitive components that ensure sprinklers activate in a timely manner are relatively fragile. In some cases, that little glass bulb — a component that’s both delicate and impacted by paint or heavy dust — is all that stands between a room and a deluge of water.

In places as diverse as prisons, hotels, courtrooms, and college dormitories, unwanted sprinkler activations have caused tens of thousands of dollars in damage. An accidental discharge can be costly, unsanitary, and inconvenient. Any replacement heads should be installed by a licensed professional who can ensure a safe installation. And any cleaning of dusty sprinklers should be done through approved touchless methods like this safe, convenient option.

VERTEX, a forensic consulting and engineering design firm, surveyed more than 30 US fire marshals from 11 states in 2017. While all of those surveyed “consider any amount of paint on the actuator, frame or diffuser to be a ‘fouled’ head,” a minority of fire marshals allowed sprinkler heads to be salvaged through paint removal “by physically touching the sprinkler head or by the use of solvents … in direct opposition to NFPA directives.”

Even if some local authorities permit paint removal, both NFPA and sprinkler manufacturers instruct not to do it. In technical documents provided with their sprinkler heads, manufacturers Viking, Senju, and Reliable explicitly warn against cleaning or even touching heads with various unapproved substances, including solvents.

Some warranties, such as Victaulic’s, are voided when the sprinkler is “used in a manner contrary to Victaulic’s instructions or recommendations.” These include warnings like these: “Do not clean sprinklers with soap and water, ammonia, or any other cleaning fluid. Do not use adhesives or solvents on sprinklers or their operating elements.”

Six digits can help you identify your replacement fire sprinkler

Many fire sprinklers can be identified by looking at the deflector plate. As long as this portion of the deflector is unpainted, check it for a five-to-six-digit sprinkler identification number, or SIN. Searching for this model number on a SIN directory, your preferred search engine, or QRFS’s search bar at the top of this page can make locating an exact replacement simple.

If the deflector doesn’t have this information, the sprinkler may have been manufactured prior to the introduction of SIN numbers. See our complete guide to replacing older sprinkler models.

If your deflector has been painted over and you can’t see the SIN, nearby sprinklers that are in the same orientation may be identical. Once you’ve figured out what you need, check out our selection of fire sprinklers, including residential and commercial models from Tyco, Viking, Victaulic, and Senju, or enter your query in the search bar at the top of this page.

If you’re not sure what you need, get in touch with us. We’ve helped a lot of people replace sprinklers of many types, including older ones that have been re-designated or are no longer manufactured.

Call QRFS at (888) 361-6662 or fill out our contact form and we’d be happy to help.

This blog was originally posted at QRFS.com/blog. If this article helped you, check us out at Facebook.com/QuickResponseFireSupply or Twitter @QuickResponseFS.