The purpose, NFPA guidance, and sought-after features of test and drain valves in fire protection systems

Ask any knowledgeable fire sprinkler contractor and they’ll tell you that a test and drain valve is a pretty handy device when installed in a fire sprinkler system. As the name implies, its dual-purpose design enables system draining when that’s needed while also aiding required testing.

But what’s the real benefit of a test and drain valve? One could easily drain the system with a ball valve, right?

That’s what we’re here to discuss in detail. In this article, we’ll inspect the test and drain valve to uncover its benefits, uses, and features. This article also digs into the relevant National Fire Protection Association (NFPA) standards so we can help you put their guidance into perspective and understand why it matters to you – the fitter, the contractor, or the building owner.

Looking for a test and drain valve? Feel free to skip directly to our selection of in-stock Test and Drains from AGF and Lansdale. Otherwise, let’s start with the basics, shall we?

What is a test and drain valve?

A Test and Drain is a type of valve with both a test function and an express drain function. Think of a ball valve and inspector’s test valve combination, except it’s manufactured as one unit, making it much more convenient.

Similar to the compact, easy-to-use nature of commercial and residential riser sets, test and drain valves are a step forward for the fire protection industry, as they simplify the installation of the system by cutting out extra components. In comparison to a standard ball valve and a separate inspector’s test valve, a test and drain means lower cost, fewer parts, easier installation, and multiple uses. With an all-in-one design, test and drain valves come standard with common features:

- A single handle ball valve

- A 5.6K or 8.0K test orifice

- Tamper resistant sight glass

- A tapped and plugged port for system access

Test and drain valves come in a variety of sizes, with specific orifice sizing options as well (we’ll discuss the importance of this in a bit). To readily serve the various system and installation needs, test and drains come in various styles with additional features. However, before we can go much further, it’s important to see how the NFPA views test and drain valves.

Is the test and drain valve NFPA-compliant?

In short, yes, the use of a test and drain is NFPA-compliant.

In a previous article, we discussed the use of ball or test and drain valves on commercial and residential risers. Upon first look at the valve section (6.6 and subsections) in NFPA 13, it seems a bit vague when it comes to test and drains specifically.

From the 2016 Edition of NFPA 13

6.6.3 Drain valves and test valves shall be approved.

That’s it? Really, that’s it.

NFPA’s reasoning is that neither drain or test valves are essential to the primary function of a fire sprinkler system vs. other valves that can do the job. But they exist, of course, and specific models must be safety approved for use within the system.

What are the uses and benefits of a test and drain valve?

Test and drain valves serve the installation and maintenance applications of wet pipe fire sprinkler systems.

From the 2016 Edition of NFPA 13

3.4.11 Wet Pipe Sprinkler System – A sprinkler system employing automatic sprinklers attached to a piping system containing water and connected to a water supply so that water discharges immediately from sprinklers opened by heat from a fire.

Wet pipe systems are undoubtedly the “Ole Reliable” in the fire sprinkler industry. They’re known for their simplistic design and consistent functionality. Other systems – like dry or deluge – have unique benefits but require more equipment, which provides more potential for system failures and shortcomings.

Because of this, the majority of test and drains are built to meet the needs of wet fire sprinkler systems. Specifically, the drain function allows the system to be drained quickly and the test function is beneficial for system testing that evaluates the water supply and ensures it’s readily available at the riser and on the system side of the main check valve.

From the 2016 Edition of NFPA 13

8.16.2.4.1* Provisions shall be made to properly drain all parts of the system.

8.16.2.4.2 Sizing the main drain connection so that it can flow the sprinkler system demand flow rate provides practical means for performing the forward flow test of the backflow device as required by 8.17.4.5.1

8.16.2.4.4 Drains shall discharge outside or to a drain connection capable of handling the flow of the drain.

Since a test and drain does have the ability to drain the system, it can serve as the main drain on a wet pipe system (8.16.2.4.8). Furthermore, test and drains can replace ball valves on commercial or residential risers.

The major benefit to a test and drain is its ability to perform necessary system testing in accordance with NFPA 25. These valves are equipped with a sight glass to provide visual confirmation of water flow through the system.

Placement of test and drain valves

From the 2016 Edition of NFPA 13

8.17.4.1.2 The test connection valve shall be accessible.

8.17.4.1.3 The discharge shall be to the outside, to a drain connection capable of accepting full flow under system pressure, or to another location where water damage will not result.

8.17.4.1.4 The alarm test connection shall be permitted to be installed in any location on a fire sprinkler system downstream of the waterflow alarm.

As stated above, there is not a specific location requirement for the test and drain valve. More traditional inspector’s test valves were placed at the end of the system, which is very useful for identifying clogs in the system. However, test and drains are commonly found as part of the riser assembly. This is A-OK!

In a combination sprinkler/standpipe system, the test and drain valve is beneficial because it helps facilitate flow testing. In order to do so, the valve must be positioned downstream of the floor control valve and connected to a drain riser. Test and drain valves have an orifice capable of simulating the discharge of a 5.6 K sprinkler head, which tests the floor’s flow switch. In this testing scenario, the water flow alarm should set off within 90 seconds. Through the water flow test, the alarm system and panel undergo testing as well, as it should indicate the flow of water.

Additionally, a test & drain can provide system security and a controlled testing environment. When used on a commercial or residential riser in a riser room, the test function is not accessible to the public and removes the risk of tampering and setting off alarms. Furthermore, the riser room can be controlled and regulated, allowing for a localized, consistent and controlled testing environment. This, in and of itself, is a major benefit!

What are the requirements of a test and drain valve?

Although we covered many of the system requirements of a test and drain in the previous section, the valves themselves must also comply with specific code.

Valves used with a wet pipe sprinkler system shall have a minimum working pressure of 175 psi. If the system has a higher working pressure, the valves must perform in accordance with the requirements of the system.

Furthermore, valves must have what the NFPA refers to as “limited leakage after removal of all resilient material.” The point of this is to show how the valve will perform during a fire or as it ages, and ensure that a large amount of water won’t flow uncontrolled into the system in the case of drain line failure.

As you move forward and begin the process of selecting a test & drain valve, it’s important to keep this information in mind.

What should you look for when selecting a test and drain for your system’s needs?

When selecting a test and drain to meet your system’s needs, you should first look for one that fits the requirements from the designer. It should also comply with any rules and regulations as set forth by the local Authority Having Jurisdiction (AHJ).

As previously mentioned, select a test and drain valve with a sight glass to provide a visual confirmation of active water flow through the system. Although they come in different sizes, a valve with a ½” orifice will simulate the flow of a 5.6K sprinkler head, which is the most common size. Otherwise, a 17/32” orifice will simulate the flow of an 8.0K fire sprinkler head, which is the second most commonly used size.

Finally, make sure to select a valve that matches the pressure rating of your wet pipe sprinkler system. According to NFPA 13, the minimum working pressure shall not be less than 175 psi.

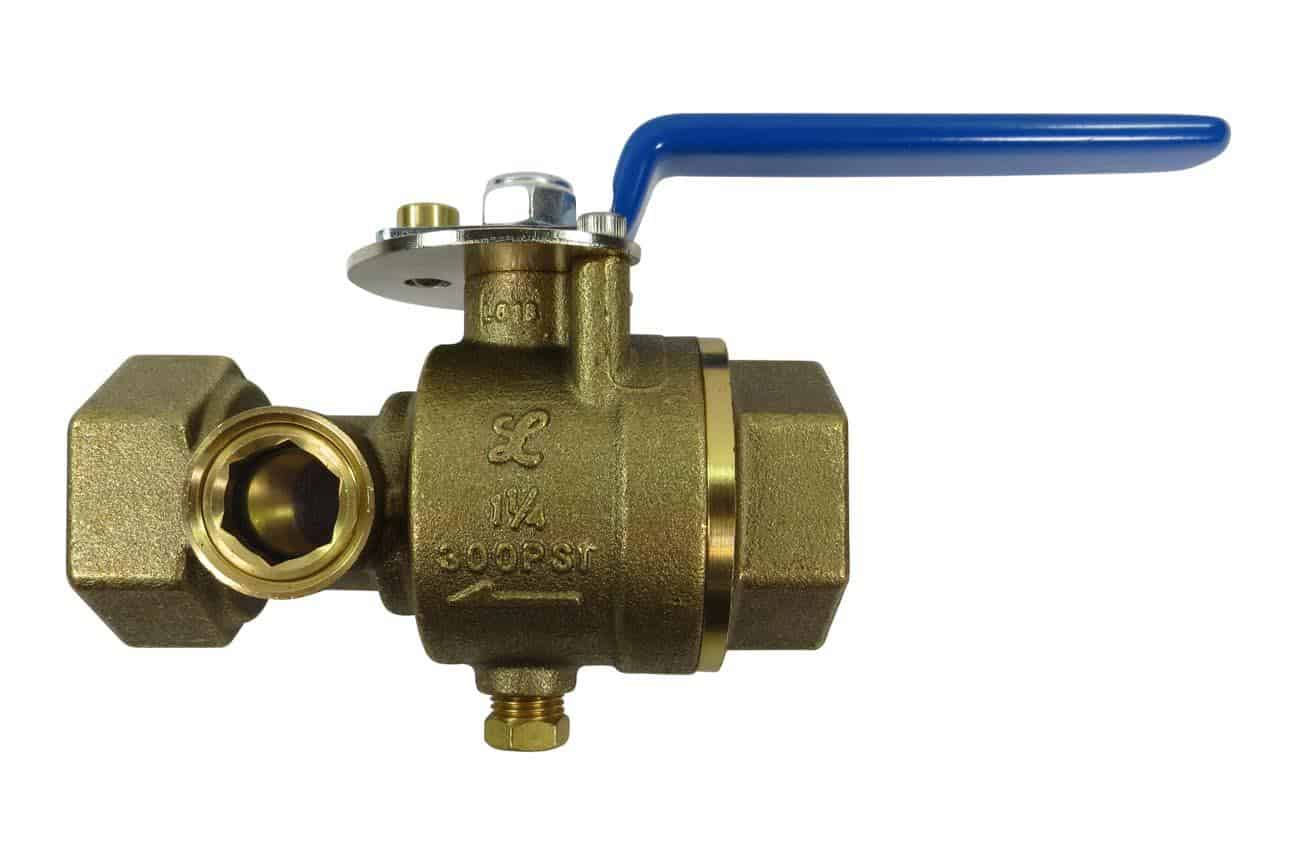

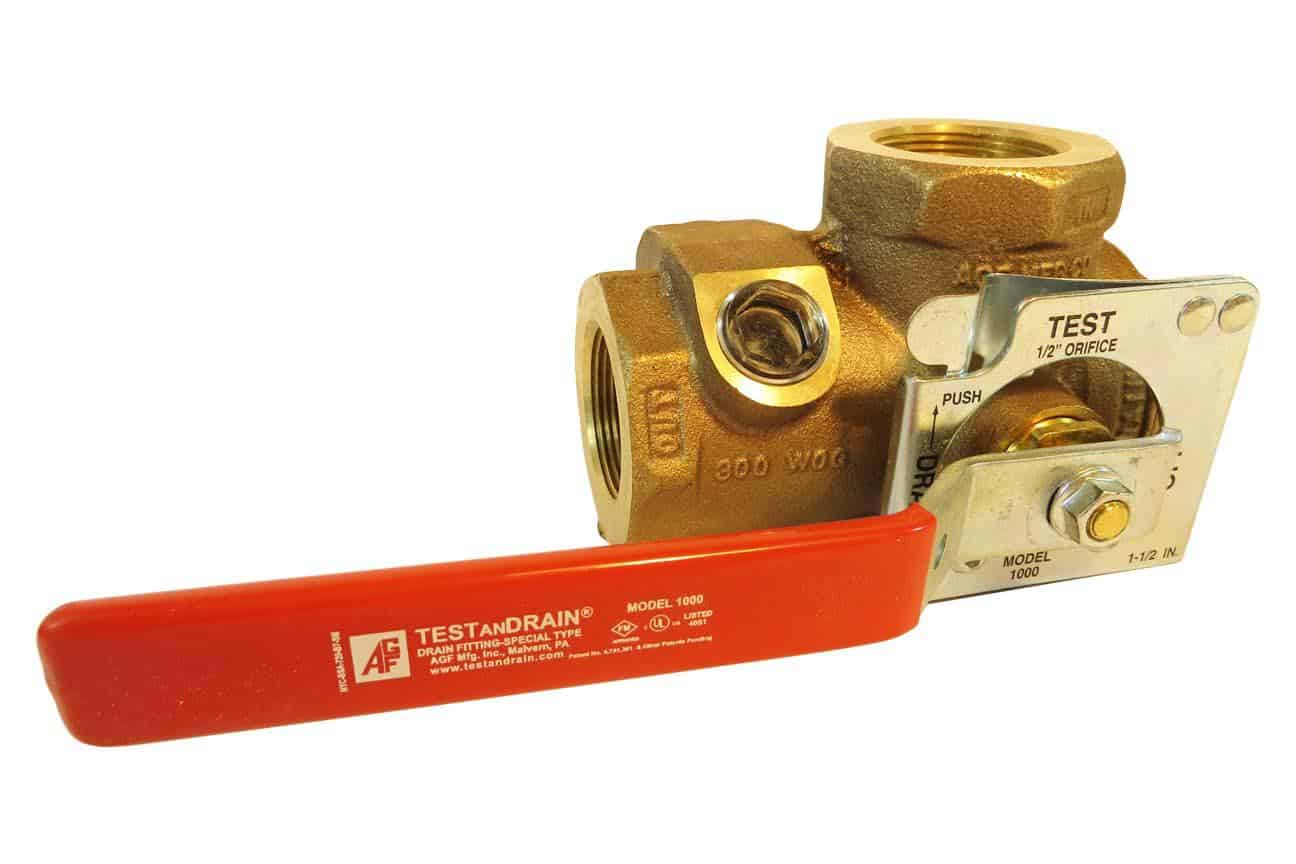

At QRFS, we offer a variety of test and drain valve makes and models to meet the needs of your wet pipe sprinkler system. AGF test and drain valves offer options with a pressure relief valve with drainage piping, pressure gauges, and three-way valves – the even make a remote-test test and drain valve. Lansdale test and drain valves provide a unique take on this valve with its patented design. All options are UL-listed and FM-approved. They are compliant with NFPA 13, 13R, 13D, and 25.

And when you purchase through QRFS, you benefit from our quality customer service and customer dedication. It’s our goal to remain up to date on NFPA standards and industry best practices, so we can help you make the most informed selection possible.

Click here to browse our selection of test and drain valves!

Or, see the table below for direct links to our Test & Drain Valve product pages.

If you still have questions, call us at 888-361-6662, email support@qrfs.com, or fill out our contact form and we’ll help get your project flowing!

| All Test & Drain Valves UL/FM Approved! | Made in the USA | Imported |

| 1″ Test & Drain Valves 1/2″ (5.6K) Orifice Thread x Thread |

AGF Model 1000 1″ Test & Drain Valve |

Lansdale 1″ Test & Drain Valve |

| 1 1/4″ Test & Drain Valves 1/2″ (5.6K) Orifice Thread x Thread |

AGF Model 1000 1 1/4″ Test & Drain Valve |

Lansdale 1 1/4″ Test & Drain Valve |

| 1 1/2″ Test & Drain Valves 1/2″ (5.6K) Orifice Thread x Thread |

AGF Model 1000 1 1/2″ Test & Drain Valve |

Duyar 1 1/2″ Test & Drain Valve |

| 2″ Test & Drain Valves 1/2″ (5.6K) Orifice Thread x Thread |

AGF Model 1000 2″ Test & Drain Valve |

Duyar 2″ Test & Drain Valve |

| TESTanDRAIN® is a registered trademark of AGF Manufacturing Inc. | ||

This blog was originally posted by Jason Hugo and Anna Hartenbach at blog.qrfs.com on August 10, 2017 and updated on January 1, 2019. If you found this article informative, check us out at Facebook.com/QuickResponseFireSupply or on Twitter @QuickResponseFS.

Technical question

If I have a sprinkler System K17 or K22 which model of test and drain can I use?

I need justify this under some standard (FM, NFPA,…)

Thanks

Jose, thanks for reaching out. For technical questions like this, we recommend submitting your question through QRFS Ask A Pro, qrfs.com/ask-a-pro. Click the link to submit your question with some information about your system, and a fire protection professional will provide a detailed answer based on standards and codes. Our pros include AHJs, contractors, engineers, and code experts with 150+ years of combined experience!

The facts that have been discussed here are really important. Thank you so much for sharing a great post.

I noticed you kind of skipped over the question about NFPA 13 requiring a valve not to close sooner than five seconds, I did not see a true answer on that question since it’s a ball valve and it can close faster than five seconds how are these legal according to NFPA 13 for fire sprinkler systems

Bruce — You are correct, and the mention of the 5-second minimum applies to indicating valves, not T&D valves. Thank you for the comment and we have updated the post.

Why when I see one of these used in 2 inch. it looks like a whole lot more water coming out in test mode than one head/orifice would provide? Seems like a lot of water to me when I see them tested. Just did a final today and at the riser the amount of water was huge and then out at the end of the zones the flow was less at the end of zone test valve and the time on the delay from the flow was significantly more delay. Seems like more than one head to me in test mode?

David — For system application questions like this, you can try our Ask a Fire Pro service. Click the link to submit your question with some information about your building, and a fire protection professional will provide an answer based on best practices, standards, and codes. Our pros include AHJs, contractors, engineers, and code experts with 150+ years of combined experience!

Tha 1/2 port has a gadge can you read flow on it when it’s in the open position