More of the top inspection violations in fire sprinkler and standpipe systems

This article is part two of our series on the top 10 fire protection compliance issues spotted by inspectors evaluating fire sprinklers and standpipes according to NFPA 25: Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems. This list is courtesy of our interview with Jack Coffelt, who works as National Operations Manager for the fire protection inspection, testing, and maintenance (ITM) contractor Siemens Industry, Inc.

Bookmark this page along with part one in the series, as it’s a great resource for avoiding deficiency tags before an inspection!

Feel free to click any of the questions in the table of contents below to view an issue and its answer, including relevant code, an explanation, and the fix. Note: The first 5 questions are covered in part one of the series.

Table of Contents

1. Is my fire sprinkler gauge too old?

2. Are my fire sprinkler pipes obstructed?

3. Are the fire pump packing glands overtightened?

4. Does my fire sprinkler system have a spare sprinkler head wrench?

5. Is my fire protection system missing the required signs?

6. Has my Fire Department Connection been hydrostatically tested within the last 5 years?

7. Do I have enough spare fire sprinklers in the cabinet?

8. Are any tamper or flow switches missing covers?

9. Are any of my fire sprinkler heads painted, caulked, or loaded?

10. Does my system have a legible, complete hydraulic calculation sign?

Here we go with the final 5!

6. Fire protection compliance: Has my fire department connection (FDC) had a hydrostatic test within the last 5 years?

NFPA 25 mandates 5-year hydrostatic testing of the “piping from the fire department connection to the fire department check valve” in standpipe systems while issuing requirements for certain types of standpipe systems. Specifically, all of the piping in semi-automatic dry and manual wet and dry standpipe systems must be tested every five years. The exception to this directive is any manual wet system that is combined with a sprinkler system.

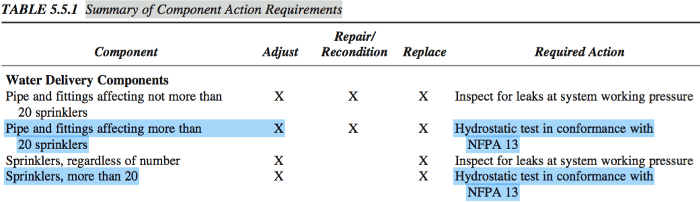

And fire sprinkler systems must also be hydrostatically tested “whenever a component in a sprinkler system is adjusted, repaired, reconditioned, or replaced,” if the revision in the “pipe and fittings [affect] more than 20 sprinklers” or if “more than 20 sprinklers” are changed (NFPA 25: 5.5.1).

If your standpipe or sprinkler system is out of compliance, get it tested! And if you are an ITM contractor and need a hydrostatic test pump, buy one here.

It’s important to remember the purpose of the fire department connection (FDC) in standpipes and sprinkler systems. Firefighters connect to the FDC to provide essential or supplemental water and pressure to serve the interior hose connections and/or sprinklers. This is crucial in manual (wet and dry) standpipe systems, especially those in multi-story buildings; without this supply, none of the interior hoses will have pressurized water.

Hydrostatic testing makes sure that the piping connecting the fire department connection to the system can withstand the pressure applied by the fire engine. Hydrostatic tests also help verify that there are no leaks in standpipes and fire sprinkler systems, which can become obvious under the extra pressure, and that the system can withstand pressure surges and operate to its expected minimum tolerances.

Here’s the relevant section:

From the 2023 edition of NFPA 25

6.3.2.1* Hydrostatic tests of not less than 200 psi (13.8 bar) pressure for 2 hours, or at 50 psi (3.4 bar) in excess of the maximum pressure, where maximum pressure is in excess of 150 psi (10.3 bar), shall be conducted every 5 years on manual standpipe systems and semiautomatic dry standpipe systems, including piping in the fire department connection.

6.3.2.1.1 Manual wet standpipes that are part of a combined sprinkler/standpipe system shall not be required to be tested in accordance with 6.3.2.1.

6.3.2.2 The hydrostatic test pressure shall be measured at the low elevation point of the individual system or zone being tested.

6.3.2.2.1 The inside standpipe piping shall show no visible signs of leakage.

6.3.2.2.2 A drop in gauge pressure of 5 psi (0.3 bar) or less shall not be considered a failure.

13.8.5 The piping from the fire department connection to the fire department check valve shall be hydrostatically tested at 150 psi (10 bar) for 2 hours at least once every 5 years.

5.5.1 Whenever a component in a sprinkler system is adjusted, repaired, reconditioned, or replaced, the actions required in Table 5.5.1 shall be performed.

To learn more about fire protection compliance and hydrostatic testing, read these QRFS articles:

- What is Hydrostatic Testing of a Building’s Fire Protection System

- Choosing a Hydrostatic Test Pump for Fire Sprinklers and Standpipes

7. Do I have enough spare fire sprinklers in the cabinet?

Just as every building with a fire sprinkler system must have a wrench that’s specific to certain sprinklers (see #4 on this list), NFPA 25 also demands an adequate supply of replacement sprinklers that match all of the existing heads within the building. The reason is simple: a damaged sprinkler means a gap in protection, and the aftermath of an activated sprinkler essentially takes the system offline. The faster the sprinkler is replaced, the faster fire protection and business can resume.

Don’t simply assume you have the cabinet, spare sprinklers, and wrench — double-check today. Missing something? Find the right spare fire sprinklers, sprinkler cabinets, and wrenches at QRFS.

Did you know that the local fire marshal can make a building owner implement (and pay for) a fire watch until the building’s sprinkler system is back in service? Avoid this hassle and expense by ensuring that you have spare fire sprinkler heads ready to go if sprinklers must be replaced. The number you need varies based on the size of the system:

From the 2022 edition of NFPA 13

16.2.7.5 The stock of spare sprinklers shall include all types and ratings installed and shall be as follows:

(1) For protected facilities having under 300 sprinklers — no fewer than six sprinklers

(2) For protected facilities having 300 to 1000 sprinklers — no fewer than 12 sprinklers

(3) For protected facilities having over 1000 sprinklers — no fewer than 24 sprinklers

Check out this QFRS article for more information: Fire Sprinkler Head Replacement Cabinet: How to Make a Sprinkler Kit.

If you’re missing anything after auditing your stock of spare sprinklers, no worries. QRFS stocks the parts you need: fire sprinklers, sprinkler cabinets, and wrenches

8. Are any tamper or waterflow switches missing covers?

According to Coffelt, waterflow and tamper switch covers are notoriously found missing during inspections. Sometimes a previous inspector removed the cover to adjust the tamper switch during testing, or perhaps a technician never tightened the screws and vibration loosened it. The cover is needed to protect the electrical and mechanical elements of the device. If the cover is available and the switch is not damaged, put it back into place. If the switch or cover is damaged, get a new control valve with an integrated tamper switch or a new tamper or flow switch.

From the 2023 edition of NFPA 25

5.2.4 Waterflow Alarm and Supervisory Signal Initiating Device. Waterflow alarm and supervisory signal initiating devices shall be inspected in accordance with Chapter 13.

13.2.3.1.1 Mechanical waterflow alarm devices shall be inspected quarterly to verify that they are free of physical damage.

13.2.3.2.1 Vane-type, paddle-type, and pressure-switch-type waterflow alarm devices shall be inspected quarterly to verify that they are free of physical damage.

13.2.5.1 Supervisory signal devices shall be inspected quarterly to verify that they are free of physical damage.

For more information on fire protection compliance and tamper switches, read What is a Tamper Switch for Fire Protection Systems?

9. Are any of my fire sprinkler heads painted or loaded?

“Loaded” sprinkler heads might be likened to a “loaded” baked potato: everything is on it. Loaded could mean the sprinkler head has some drywall compound or, most commonly, excessive dust and dirt. If this is the case, it’s a fire protection compliance problem and the sprinkler head must be replaced—unless a sprinkler that is light-to-moderately loaded can be cleaned if the head is not touched or damaged. If you need replacement sprinkler heads, buy them here. If you have to clean a sprinkler loaded with dirt and dust, a SprinklerVac provides a safe, touch-free way to do it.

Nearly every code and standard (NFPA 13 and NFPA 25) has language that prohibits a painted or loaded sprinkler. Why? Paint, dust, or other materials can coat the heat-sensitive link or bulb and delay operation. In addition, paint can seal the sprinkler’s deflector or cap that covers the orifice in the body of the sprinkler, limiting activation or altering the spray pattern. Paint or caulk, as shown below, can also prevent a cover plate from dropping off to expose the sprinkler.

In previous editions of NFPA 25 (many of which are still referenced by code enforcers today), any drop of aftermarket paint anywhere on the sprinkler technically called for replacing it. But the latest 2023 edition of NFPA 25 provides some leeway, adding the words “detrimental to sprinkler performance” on item six:

From the 2023 edition of NFPA 25

5.2.1.1.1* Any sprinkler that shows signs of any of the following shall be replaced:

(1) Leakage

(2) Corrosion detrimental to sprinkler performance

(3) Physical damage

(4) Loss of fluid in the glass bulb heat-responsive element

(5) Loading detrimental to sprinkler performance

(6) Paint, other than that applied by the sprinkler manufacturer, detrimental to sprinkler performance

For information on painted sprinklers, including what qualifies as paint “detrimental to sprinkler performance,” read these blogs:

- Help! My Fire Sprinkler Was Painted. What Should I Do?

- Fire Sprinkler Head Replacement: Changes to NFPA 25 Rules

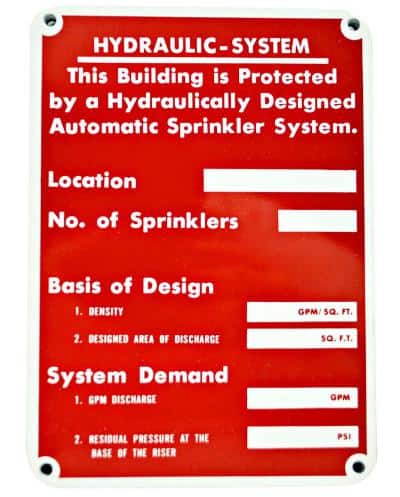

10. Does my system have a legible, complete hydraulic calculation sign?

Hydraulic information signs, sometimes referred to as “hydraulic calculation signs” or “calc plates,” are important for the maintenance of the system. Often, a building owner has lost the original plans, acceptance tests, and design documents, and this sign lists much of this vital information. NFPA 25 requires missing calc plates to be replaced. Even when they are present, the information is sometimes incomplete or impossible to read. If your sign is illegible, make it readable. If it’s missing info, consult the original document or installation contractor and fill it in. And if it’s not there at all, buy a new one.

Section 29.4.1 of NFPA 13’s sprinkler system acceptance requirements (2022 edition) specifies that all hydraulically designed sprinkler systems must have “a permanently marked weather-proof metal or rigid plastic sign secured with corrosion-resistant wire, chain, or other approved means. Such signs shall be placed at the alarm valve, dry pipe valve, preaction valve, or deluge valve supplying the corresponding hydraulically designed area.” (29.4.2)

From the 2022 edition of NFPA 13

29.4.3 The sign shall include the following information:

(1) Location of the design area or areas

(2) Size (area) of or number of sprinklers in the design area

(3) Discharge densities over the design area or areas

(4) Required flow and residual pressure demand at the base of the riser or fire pump where applicable

(5) Occupancy classification or commodity classification and maximum permitted storage height and configuration

(6) Hose stream allowance included in addition to the sprinkler demand

(7) Name of the installing contractorFrom the 2023 edition of NFPA 25

5.2.5* Hydraulic Design Information Sign.

The hydraulic design information sign shall be inspected annually to verify that it is provided, attached securely to the sprinkler riser, and is legible.

5.2.5.1 A hydraulic design information sign that is missing or illegible shall be replaced.

Note: If you have an older system with a pipe schedule design, you must also have a sign indicating that this is the nature of the system.

Another note: NFPA 13 also requires a “general information sign” that has a great deal of data, some of it overlapping with the items on the hydraulic information sign. Thus, more recent editions of NFPA 13 allow systems to have a combination sign conveying the relevant information in both signs (29.6.3).

For more on hydraulic data and other signage, see our Guide to Fire Sprinkler Signs and System Marking and if you need to replace a missing sign, QRFS has it.

This concludes The 10 Most Common Fire Protection Compliance Issues and How to Avoid Them

Be sure to read and bookmark part one if you haven’t checked it out. As always, we’re available to answer any questions or help you find parts for your fire sprinkler or standpipe system. Get in touch at 888.361.6662, support@qrfs.com, or through our contact form.

This blog was originally posted at QRFS.com/blog. If this article helped you, check us out at Facebook.com/QuickResponseFireSupply or Twitter @QuickResponseFS.